Marzhan Anuarbekovna Sadenova

Candidate of chemical Sciences

Email: [email protected], [email protected]

Tel.: +7 777 2029794

In the Center of Excellence "Veritas" of D. Serikbayev EKTU under the leadership of a leading researcher Marzhan Anuarbekovna Sadenova, research is being conducted to develop a technology for producing ceramic carriers for catalysts for neutralizing various gases.

The technology consists in the synthesis of ceramic carriers and / or catalysts from a mixture of natural aluminosilicates and metallurgical slags.

This technology can be part of the approach to organize the work of enterprises with a low level of waste and the gradual introduction of "waste-free" technologies in various industries.

Aluminum silicates-zeolite and bentonite are used as the main raw materials in the technology for producing ceramic carriers for gas neutralization catalysts and metallurgical slags of lead and copper production are used as an additive-regulator of the properties of ceramics. The Cu-Ni-Cr system was chosen as the active components of the catalyst while varying the amount and method of metal deposition.

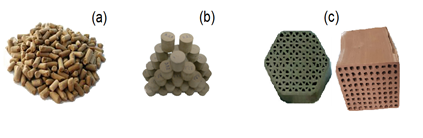

Powder metallurgy methods are used to obtain ceramic catalyst carriers of various configurations. The application of the catalytic mass to the surface of the carrier was carried out from aqueous solutions of salts of active components by the method of capillary impregnation by moisture capacity.

Preliminary data show that all obtained zeolite-bentonite slag catalysts provide a catalytic conversion of the carbon-containing components of the gas mixture by α ≥ 70%.

The catalysts were tested during the oxidative conversion of CO and CH4 to CO2. These toxic components are present in the gas emissions of thermal power plants, industrial enterprises, boiler plants, motor vehicles and others.

The advantage of this technology is the use of natural raw materials and man-made waste, which presumably not only reduces the cost of finished catalysts and increases their availability but also allows you to involve metallurgical slags in the synthesis of new products in demand. The use of slag in catalysis is a new and promising scientific and technological direction.

The possibility of obtaining materials based on natural raw materials and man-made waste is well studied all over the world mainly for the construction industry. This technology will make it possible to obtain new ceramic materials suitable for use in environmental catalysis.

Experimental samples of synthesized ceramic materials containing slag in the form of (a) granules, (b) tablets, (c) blocks.

Experimental samples of synthesized ceramic materials containing slag in the form of (a) granules, (b) tablets, (c) blocks.

International cooperation office: [email protected]